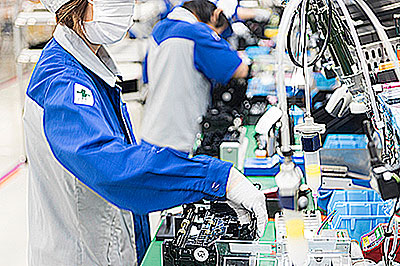

Versatility, the ability of several people to carry out various types of work, rather than having a single person in charge of one operation, forms the foundation of how we train our employees. Master craftsmen of scanner manufacturing are in charge of producing our products. If each employee could only perform one operation, large shipment fluctuations would result in an inability to deliver to our customers on time. However, if employees are versatile, human resources can quickly be focused on production of high-demand, high-priority products, which allows us to provide the required models consistently and without loss of quality.

Fusion of Master Craftsmen's Technical Skill with Advanced Systems

Offering Various Models Through Versatility

In the training room at our factory in Japan, employees can learn a variety of scanner manufacturing skills and experienced workers can share their knowledge with newer staff.

Products of Consistent Quality to All

We implemented an assembly support system on the lines at our manufacturing sites characterized by strong IT technology support. The system includes digitized procedure manuals and records of past operations, which provide a structure that ensures consistent, high quality regardless of who works on the production line. It also allows us to track specifically where and why defects and malfunctions occur, so that we can continually improve on our manufacturing processes.

Effective manufacturing line introducing an assembly support system

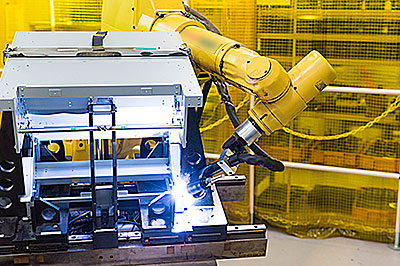

Manufacturing robot which can weld sheet metal without even the slightest deformity

Tracing information management by scanning boards with the "ScanSnap SV600"

Highly Accurate Alignment of Technology and Machine

Ricoh manufacturing is a fusion of the "master craftsman" style and advanced technology. This is evident on the manufacturing line for optical units, which are one of the most important parts in a scanner.

Production of optical units requires a high level of accuracy in manufacturing, as even a slight difference between components makes all the difference in quality. Therefore, only experienced employees who have passed our rigorous certification test can produce optical parts, and they assemble parts by hand in cases where it is difficult to assure quality by machine. At the same time, we ensure consistency by using our unique measuring instruments to evaluate whether the optical parts meet our high-accuracy standards.